Sustainability at SEGGER

SEGGER has always been very environmentally conscious and friendly, always working to minimize resource and energy usage in the production of its products as well as the energy use of the products themselves.

Designing software for sustainability

SEGGER’s embedded software helps make our customer’s products more energy efficient. The high performance and small memory requirements of all SEGGER software components result in customers being able to use smaller chips with lower power requirements.

Innovative software – embOS-Ultra

The revolutionary real-time operating system embOS-Ultra avoids the usual system tick interrupt. This keeps the processor in energy-saving mode for longer periods of time and thus reduces the application's energy requirements.

Reducing power consumption for billions of devices

Reducing energy use by small amounts, multiplied over billions of devices and many years, helps make a difference in the power usage of SEGGER and its customers.

One example is SEGGER's famly of J-Link debug probes. These have always been very energy efficient. The use of embOS-Ultra further reduces energy consumption by about 17 %. All J-Links are USB powered and use less than 1W.

Another example is that no SEGGER product uses a fan, yet many of its products use less power in total than the fan alone in some competing products.

Creating long-lasting hardware

While SEGGER hardware products are well known for their performance and reliability, SEGGER’s engineering teams are also well known for their highly efficient use of resources and dedication to waste reduction.

Optimization starts with the use of our own software libraries for creating the firmware of the debug probes, trace probes and production programmers.

Reducing product sizes for less energy and resource usage in production

For all of its popular hardware products, SEGGER offers compact versions with the same functionality in a significantly smaller housing. This reduces energy and resource usage in production as well as waste in packaging and emissions from shipping.

The J-Link PLUS Compact and J-Link BASE Compact debug probes provide the same functionality as their Classic equivalents but in much smaller packages.

Similarly, the Flasher Compact is a full-featured in-circuit universal flash programming tool (ICP) in a housing with a base area smaller than that of a credit card.

Corporate carbon footprint

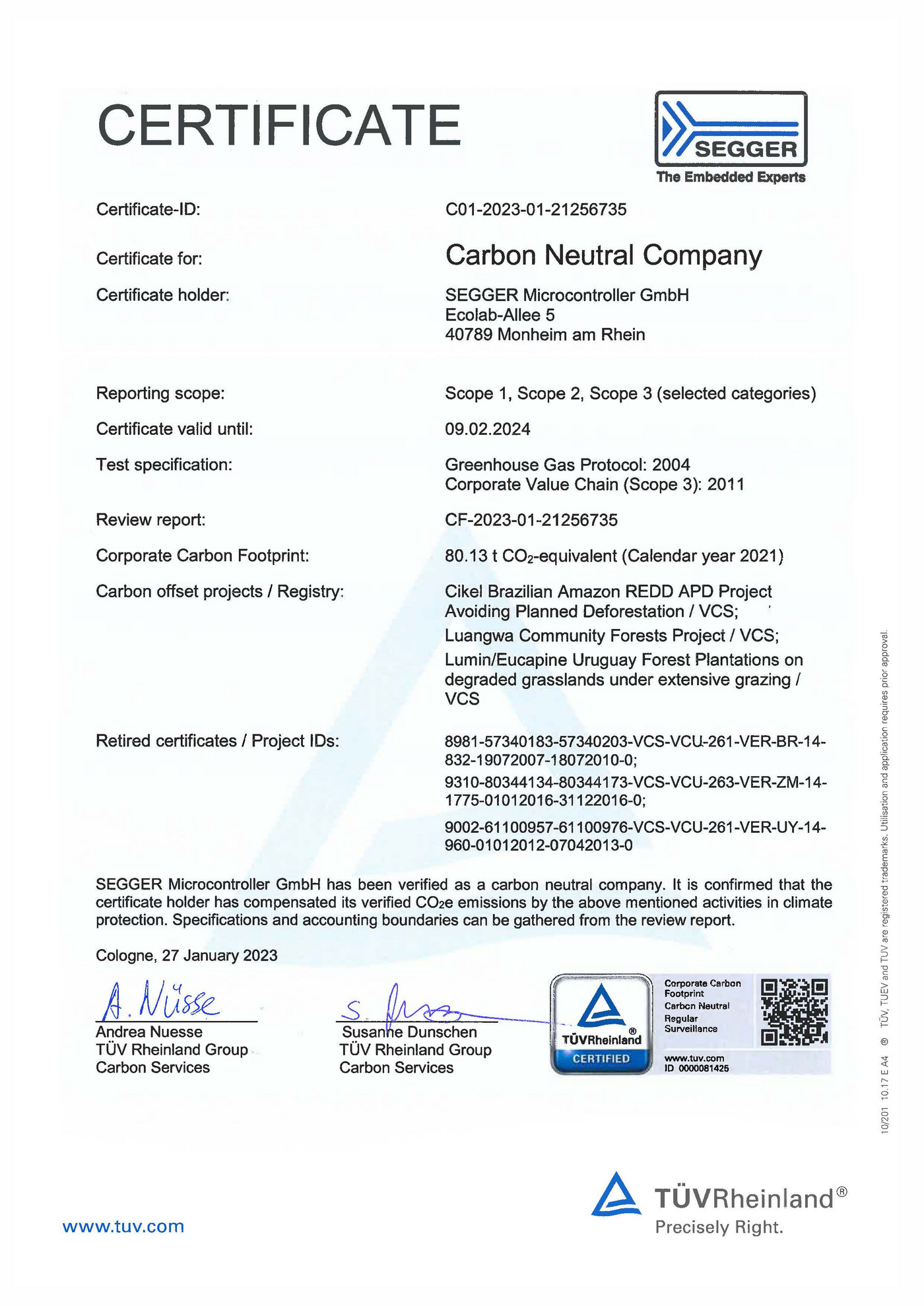

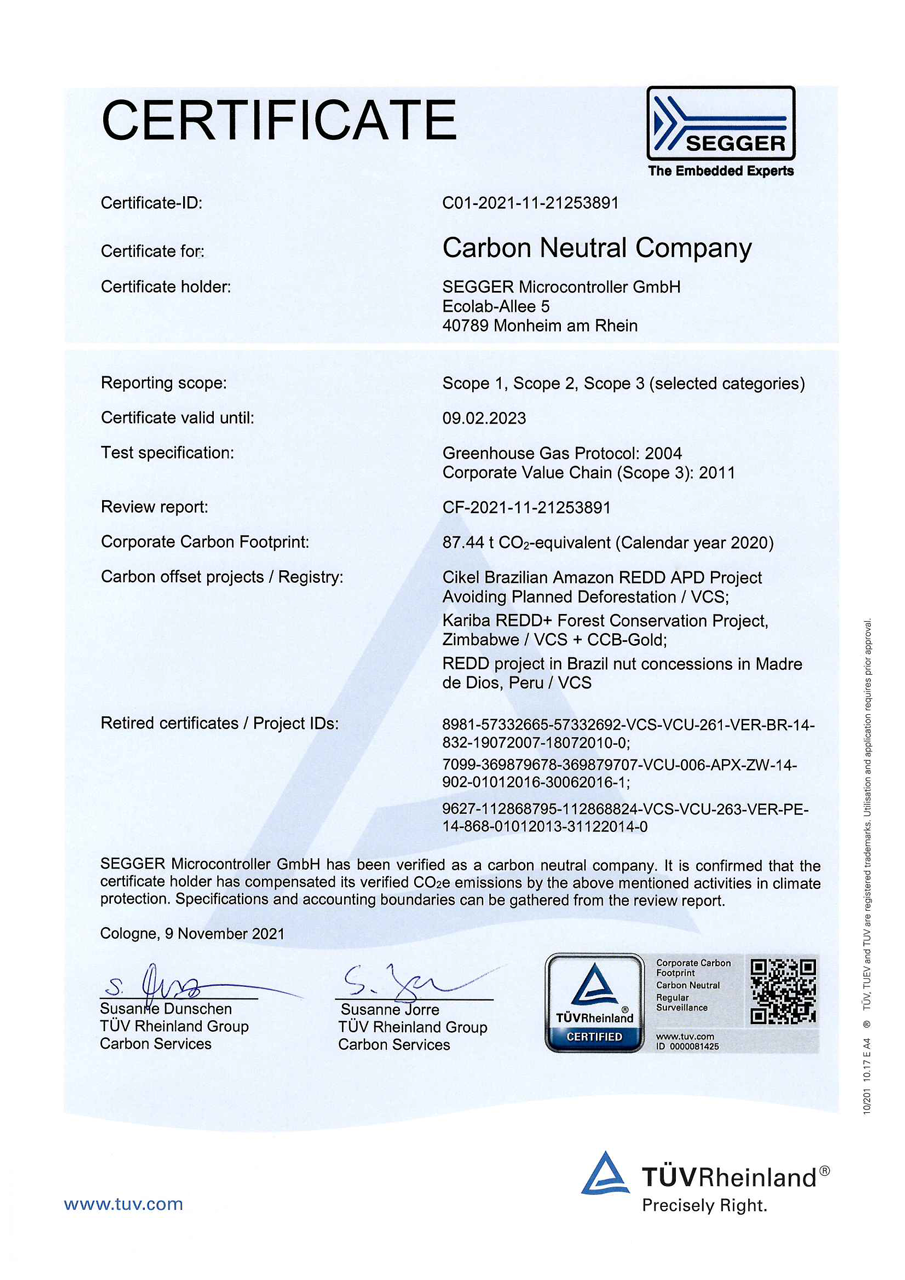

On November 9, 2021, TÜV Rheinland issued SEGGER a certificate of climate neutrality.

SEGGER has always strived to be environmentally friendly. In 2020, SEGGER generated emissions equivalent to just 87.44 t CO2, which is already very low.

In 2021, SEGGER took the logical next step, namely to become CO2 neutral. To do this, SEGGER purchased CO2 certificates to compensate for its emissions. The supported projects are described in detail below. The final step was the certification of the process by TÜV Rheinland, after which SEGGER can now rightfully claim to be carbon neutral.

A copy of the certificate can be found in the TÜV Rheinland database:

https://www.certipedia.com/quality_marks/0000081425?locale=en

SEGGER’s long-term plan is to become operationally carbon neutral by focusing on energy efficiency.

On January 27, 2023, TÜV Rheinland renewed SEGGER's certificate of climate neutrality.

Energy efficient office buildings and infrastructure

In terms of operations, in 2018 SEGGER built new headquarters using energy-efficient construction material and state-of-the-art heat pump technology. SEGGER has now decided to add a 99 kW solar carport. The green power produced will support charging stations for an additional 34 electric vehicles as well as the building itself.

All new company vehicles will be electric, where possible, or hybrid, where necessary. SEGGER also maintains a fleet of company bicycles for its employees.

SEGGER is in the planning stages of a new office building for expansion. In addition to efficient insulation and energy-saving technology, the new building will have a facade of solar panels thus producing even more renewable energy on site.

Zimbabwe: Protecting forests & providing sustainable livelihoods

The Kariba REDD+ Project is located in northwestern Zimbabwe. It lies partly along the southern shore of Lake Kariba and spans four provinces. To reduce deforestation within the project area of approximately 1.4 million hectares, the community-based project implements a series of activities that are designed to significantly improve livelihoods of the locals – for example, improved agriculture, beekeeping, fuelwood plantations and fire management.

In addition, a significant share of the project’s carbon income will be invested in general activities that promote and guarantee project sustainability. The project’s Community and Project Sustainability Fund is structured to benefit local communities, specifically the poorest members of society. The fund will be used to improve health and education in the project area with its long-term activities.

Source: First Climate

Peru: Avoiding deforestation

The Rainforest Community Project brings together hundreds of local families and small-scale concession holders which harvest Brazil nuts in the Peruvian Amazon. Through investment from the project, these nuts can be sustainably harvested, processed and sold directly to international export markets for the first time. The project provides a viable alternative to deforestation in providing sustainably generated income for local communities.

Experience in past decades shows that better access increases deforestation for agriculture and illegal logging. This project comprises of two forestry concessions that are managed in line with Forestry Stewardship Council (FSC) guidelines. The concessions stretch over 100,000 hectares covered by dense rainforest. Effective surveillance of this area to prevent illegal dwelling and destructive forest use is only possible with the support of carbon certificate revenues.

Brazil: Avoiding deforestation

The project covers an area of 27,434 ha in the state of Pará, Brazil. The area is part of a privately owned forest, which is managed by CKBV Florestal Ltda. Since 1977, the company has predominantly traded timber products, but suffered severe financial losses in 2005 and 2006, causing them to change their business strategy.

The project area was initially planned to be legally logged and converted into pasture for livestock grazing. As pure forest protection is not financially viable, the sale of carbon credits makes sustainable forest management economically competitive with livestock farming. It is estimated that the avoided deforestation as a result of the project will avoid the emission of around 372,707 t CO2 every year.

Source: First Climate